Any car that has a combustion engine will have a purge valve. And when it gets bad your car can get stuck anywhere and anytime and sometimes it may be dangerous. Thus, testing a purge valve and its maintenance is required on a regular basis. In this comprehensive guide, we will explore the step-by-step process of testing the EVAP purge valve using a multimeter, empowering you to troubleshoot and address potential issues effectively. How can you ensure your vehicle’s EVAP purge valve is functioning correctly to maintain optimal performance?

Testing a purge valve is not a tough task if you know the basics mechanics of the car, you can do it yourself at home. But before we come to the essential steps for testing the purge valve, let’s understand what this purge valve is.

What is a Purge Valve?

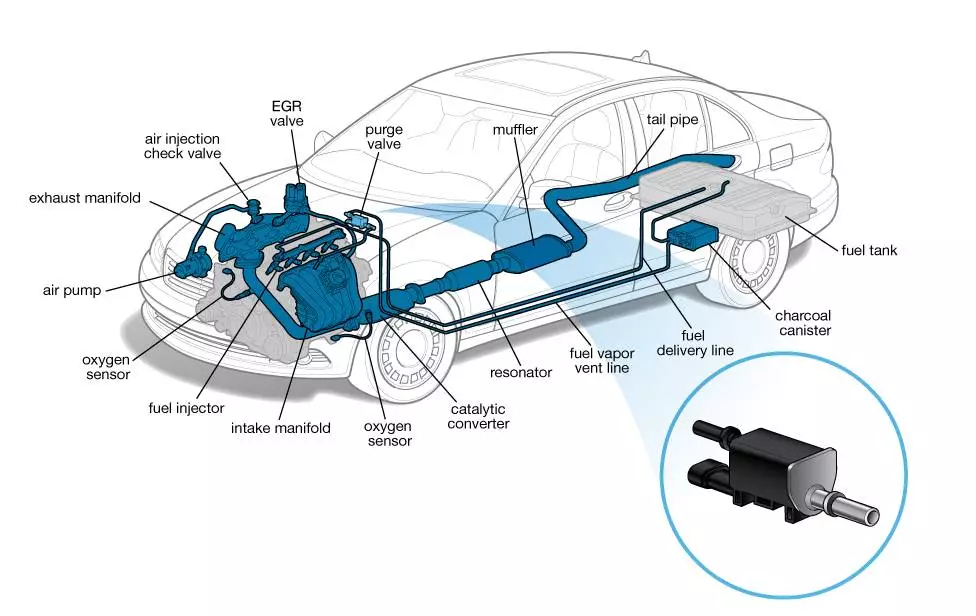

A purge valve is a significant part of the Evaporative Emission Control Systems (EVAP) that assists with expanding eco-friendliness and diminishing outflows. During ignition, the EVAP purge valve keeps fuel fumes from getting away into the climate by putting it inside a charcoal canister.

When the Powertrain Control Module (PCM) conveys a signal to the purge valve, this fuel fume is delivered into the motor for ignition, going about as an optional source of fuel. While doing this, the PCM guarantees that the purge valve opens and closes with perfect timing to deliver the perfect proportion of fuel fumes to the motor.

What is the Purpose of the Purge Valve?

The purge valve controls the quantity of fuel vapor that is launched from the charcoal canister and returned to the engine for combustion. The EVAP machine will slowly permit fuel vapors to be discharged into the engine, which burn like ordinary fuel. The canister purge valve will manipulate those flows and alter the quantity of vapor in order to enter the engine.

How to Test Purge Valve?

There are four main ways by which I will answer your query on how to test purge solenoid valves. Let’s discuss each step toward testing a purge valve in detail.

1. Continuity Test:

To test a purge valve, the safest and quickest way is the continuity test.

To perform a continuity test, you must remove or disconnect the purge valve from the engine. This is easily done by removing the clamps for the inlet and outlet hoses from the engine and fuel tank. Make sure the car is idle for at least 30 minutes. If you are not satisfied, contact a mechanic or take the car to the car service station.

Once you have the purge valve, set the multimeter to continuity mode. Continuity mode is a mode in which the multimeter makes an audible sound when you touch two probes in unison. Connect the probes to the purge valve, and power terminals.

For testing a purge valve, check the sound – if you hear an audible beep sound, the purge valve is working. This is because most purge valves are solenoid purge valves. This means there is a copper/metal coil in the positive and negative power terminal purge valve casing. Now, how to tell if EVAP purge solenoid is bad? If you do not hear any sound, the purge valve is damaged and needs to be replaced.

2. Check The Ohm Meter Reading:

How to test the EVAP purge valve using an Ohm Meter? Simply, turn the multimeter knob so that it is on the ohm-meter scale. Take the 2 probes and place them on the purge valve electrical terminals. The multimeter should give you a reading. Usually, a reading of 14 to 30 ohms means the purge valve is fine.

If you have readings above or below this range, there may be a problem with your purge valve and it needs to be replaced. And it is done. This is how the purge valve is tested using a multimeter. There are a few more ways to test the purge valve with a multimeter.

3. Mechanical Click Test:

How to test the canister purge valve? For this, you can also go by the mechanical test. This test checks that your purge valve is working when voltage is applied to the terminals. Very easy to set up and operate. First, take your probes and connect them to the 12V battery terminal. Second, connect the other ends of the probes to the purge valve terminals. Now, how to tell if EVAP purge solenoid is bad? If you hear a click, your purge valve is working properly. If it does not click, the purge valve is damaged and needs to be replaced.

4. Close Test:

Close test is the last way how to test purge solenoid valves in a fourth manner. This test will tell you if the purge valve is causing the vacuum leak or not.

First: I want you to connect a 5/8-inch hose to the end of the drain valve that goes into the engine intake manifold. Don’t forget to tighten the clamps.

Second: Connect the other end of the hose to the hand vacuum pump.

Third: Inflate the hand vacuum pump to about 20 or 30 in-Hg/mm-Hg.

Leave it there for about 2 to 3 minutes. What you need to see is that vacuum pumps may not leak air (hence the reduced value). If this happens, it means that there is an air leak between your purge valve or that the connection between the hose and the purge valve is not functional. This is how to test the EVAP purge valve. If you see this, make sure the hose is connected correctly. Then run the test again.

If it still fails – your purge valve is damaged. If after 2 or 3 minutes the vacuum pumps read almost the same, remove the probes and connect them to the 12V battery source. Then connect the other side of the probes to the purge valve terminals. So, how to tell if EVAP purge solenoid is bad? If you hear a click and the vacuum pump quickly goes to 0. Then your purge valve is working properly.

In the End…

Now that you are familiar with the 4 important steps to test a purge valve with a multimeter, bookmark this blog so you can come back to it when you need this information again about how to test a canister purge valve. You can also get some more information about Purge Valve through the below-mentioned FAQ.

A word of caution – make sure you are familiar with safety protocols when doing this kind of work to test a purge valve. If you are not comfortable testing purge solenoid valves, it is best to have a mechanic help you.

FAQs:

1. How long can you drive with a bad purge valve?

You can still drive your vehicle with a faulty purge valve, but it’s important to address the issue as soon as possible to prevent any further negative impact on your car’s performance.

2. What is the resistance of a purge valve?

A healthy purge valve is expected to have a resistance between 14 Ohms and 30 Ohms, depending on the model. How to test purge solenoid valves? If the multimeter reads higher or lower than the appropriate range, then your purge valve is faulty and needs to be replaced.

3. How long does a purge valve last?

Purge valve life varies depending on vehicle type and driving conditions. In general, the relief valve should last 50,000 kilometers. However, if your car is driven in extreme conditions, the valve should be replaced regularly. Testing a purge valve regularly will help you drive easily.

4. What happens if the purge valve is stuck closed?

The stuck purge valve prevents the system from burning vaporized fuel in the engine. This will cause a low purge flow code and may cause premature failure of the activated carbon canister in the evaporation system.

5. How do I know If my purge valve is stuck open?

While testing a purge valve, it being stuck open is a high chance. So how do you check if the purge valve is open? The car will give you signals like misfires, rough running, or difficulty starting the vehicle. This is because excess fuel vapors are supplied to the engine by a stuck open purge valve.